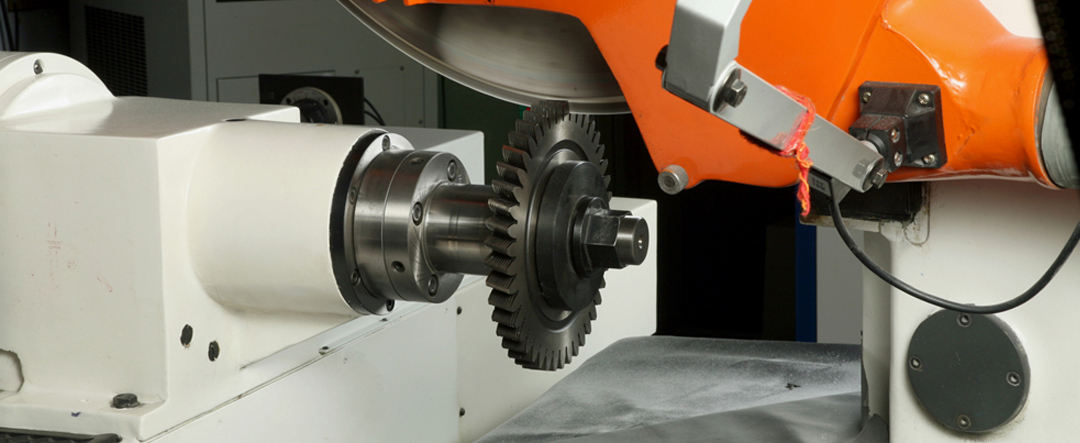

In contemporary industrial applications, cutting tools offer better performance and a wider variety of outcomes. There are several applications for precise measurement-taking tool-making cutters. Conversely, shaving cutter aim to fulfill specifications with a high degree of strength and accuracy. Moreover, appropriate adjustments to gear shaving cutters will lower the return. On the other hand, compared to rival products, it produces less noise and generates more torque. In the limited area, noise reduction techniques ought to be used.Essentially, tool cutters are always used in conjunction with cutting solutions.

- Precision and accuracy guaranteed

Gear cutters encourage effective operation and manage demand. Because of the enhanced performance and power distribution, everything will keep operating as usual. Using the most suitable settings, they are all removed. Everything hinges on the necessary adjustments being performed. New medications and efficient treatments will result from this. It is therefore ideally suited to a wide range of industrial applications. For heavy-duty applications, these are highly recommended and taken into consideration. Consequently, the business produces the most cutting-edge machinery and industrial solutions. They preserve current arrangements while adapting to new advances in the legal system.

- Superior gear quality

This gives the gear cutter full control over the choice and allows it to monitor the growth of the energy supply. A shortage of clearance between the milling cutting tool and the shaping machine tool might be caused by a small interference at the right place. To attain even distribution, the bevel tool is adjusted and the gap is reduced. It executes updates more quickly and considers performance goals. Sound settings are necessary and produce better outcomes more quickly than expected. To cut down on noise, the tool cutters must work harder. The power supply must be reliable and efficient for today’s applications.

- Advanced materials and coatings provided

To obtain a complete stability setting and lessen backlash for quicker, more precise outcomes, a unique locking nut is utilized. Because they can be adjusted to the required quantity and quality and guarantee high quality, they are the best electrical equipment for new projects. Modern gear cutters are frequently used in electric stoves to supply direct current electricity. It facilitates faster thinking at work. It provides long and spiral designs in similar finishes and sizes. Replacement parts are used for repairs due to the limited range. Tool cutters and hobs are now more efficient thanks to calculations. They consistently offer the best gear shaper cutters, which are strong and effective.

- Reliable supply chain and expertise

In addition to being effective, the gear shaper cutters are quite flexible when it comes to power producing machinery. The flexibility of this gear cutting machinery guarantees that they can fulfill their commitments and develop new manufacturing techniques, providing users with a sense of confidence. Therefore, gear shaving cutter manufacturers are frequently utilized to identify shifts in manufacturing ranges. They create innovative production techniques and fulfill their promises. Investigating the modifications made to the gear cutting and shaper tooling needs is therefore required.